sustainability

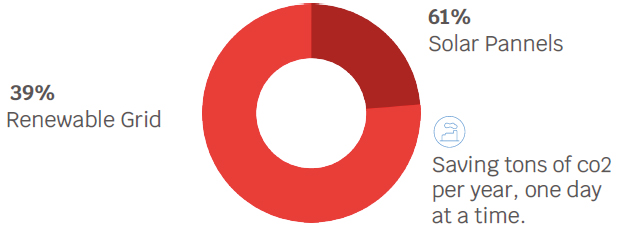

In 2020, we took a significant step towards sustainability by acquiring our initial set of solar panels. Since then, we’ve expanded the panel capacity and implemented precise measurement systems to track their output and usage. This allows us to accurately gauge the impact of our solar energy generation, leading to a reduction in our environmental footprint. Through optimal use of solar energy, we align our operations with specific needs, maximizing benefits.

2023 energy Sources

Over the last few years we have implemented the various relevant Certifications, including the Global Organic Textile Standard (GOTS), Global Recycled Standard (GRS), and Sedex Members Ethical Trade Audit (SMETA) as well as Responsible Wool Standard (RWS), play a pivotal role in TMR’s sustainability

SMETA certification for ethical and responsible sourcing.

RWS certification for responsible wool sourcing.

Development of a customizable line with a product passport, making fair and certified production accessible to small brands (using only mono-fiber materials).

Implementation of 3D sampling to reduce waste and minimize the need for pre-production samples.

Making our deadstock available for purchase or production by smaller brands.

Pilot projects with clients for 3D size sets of prints and embroideries for approval.

Increase the capacity of our solar panels by up to 20%.

Increase the number of hybrid cars to 2 and install 2 electric vehicle charging stations in the factory.

Implementing sheet-by-sheet cutting to reduce paper and plastic waste in cutting, targeting a reduction of 40% and an energy reduction of 50%.

Procure additional Naomoto irons to enhance finishing quality, reduce energy consumption, and improve work quality by providing a safer and more efficient workplace environment.

goals 2024

One of our big goals and priorities for 2024 is finalizing the BCORP Certification which will ensure that our company is meeting high standards ranging from social and environmental performance to transparency.

Acquire one fully electric car with a range of at least 200 kilometers.

Create a Pension Plan (PPR) for employees aged 45 and above.

Development of a customizable line with a product passport, making fair and certified production accessible to small brands (using only mono-fiber materials).

Implementation of 3D sampling to reduce waste and minimize the need for pre-production samples.

Introduction of reusable packaging for sending samples within the company.